Digitize maintenance in 8 weeks!

Maintenance software is one of the most important tools for maintenance. With Scable you can keep track of everything important even on a turbulent day. Our software is user-friendly for both maintenance employees, specialists and managers.

Popular modules

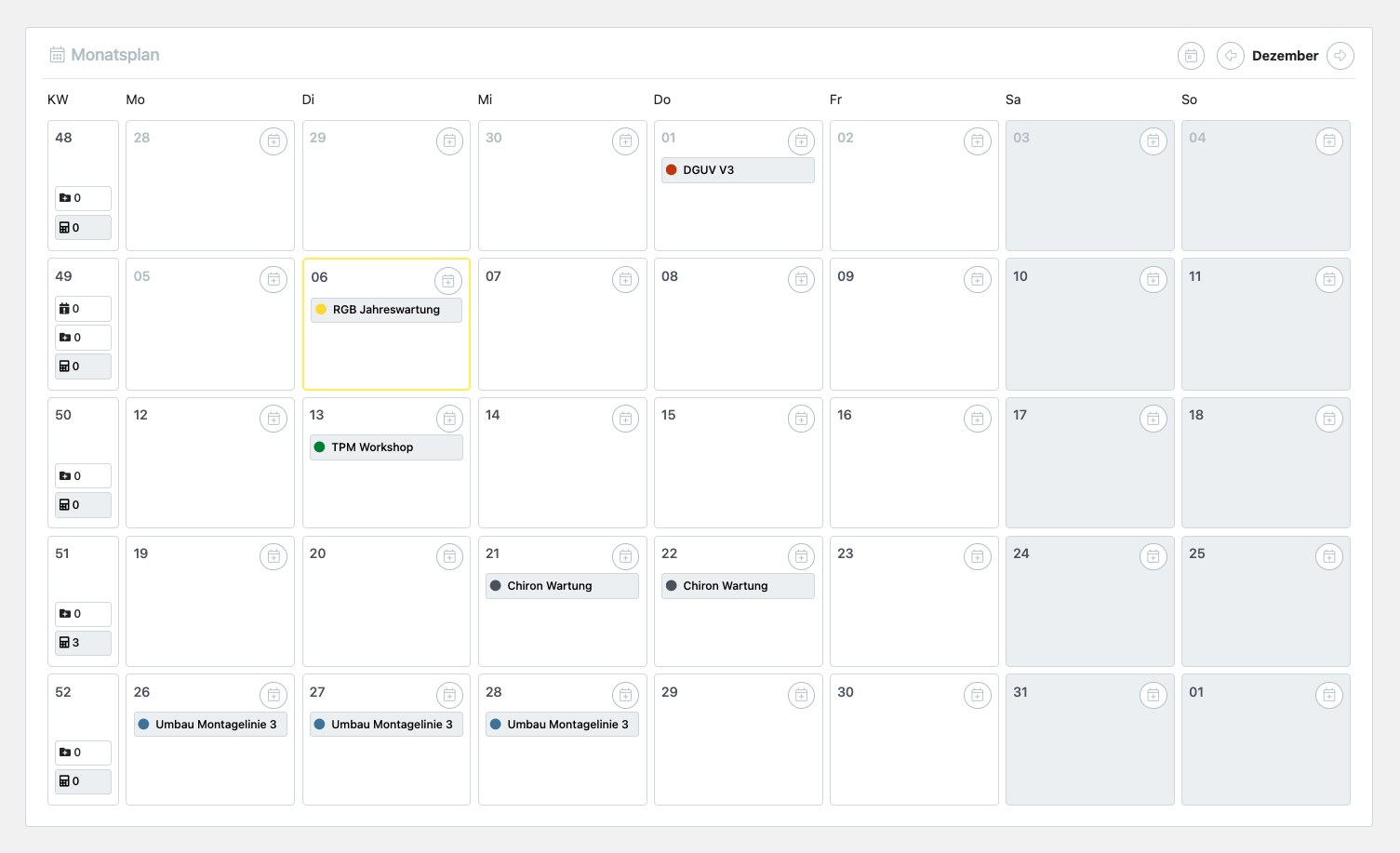

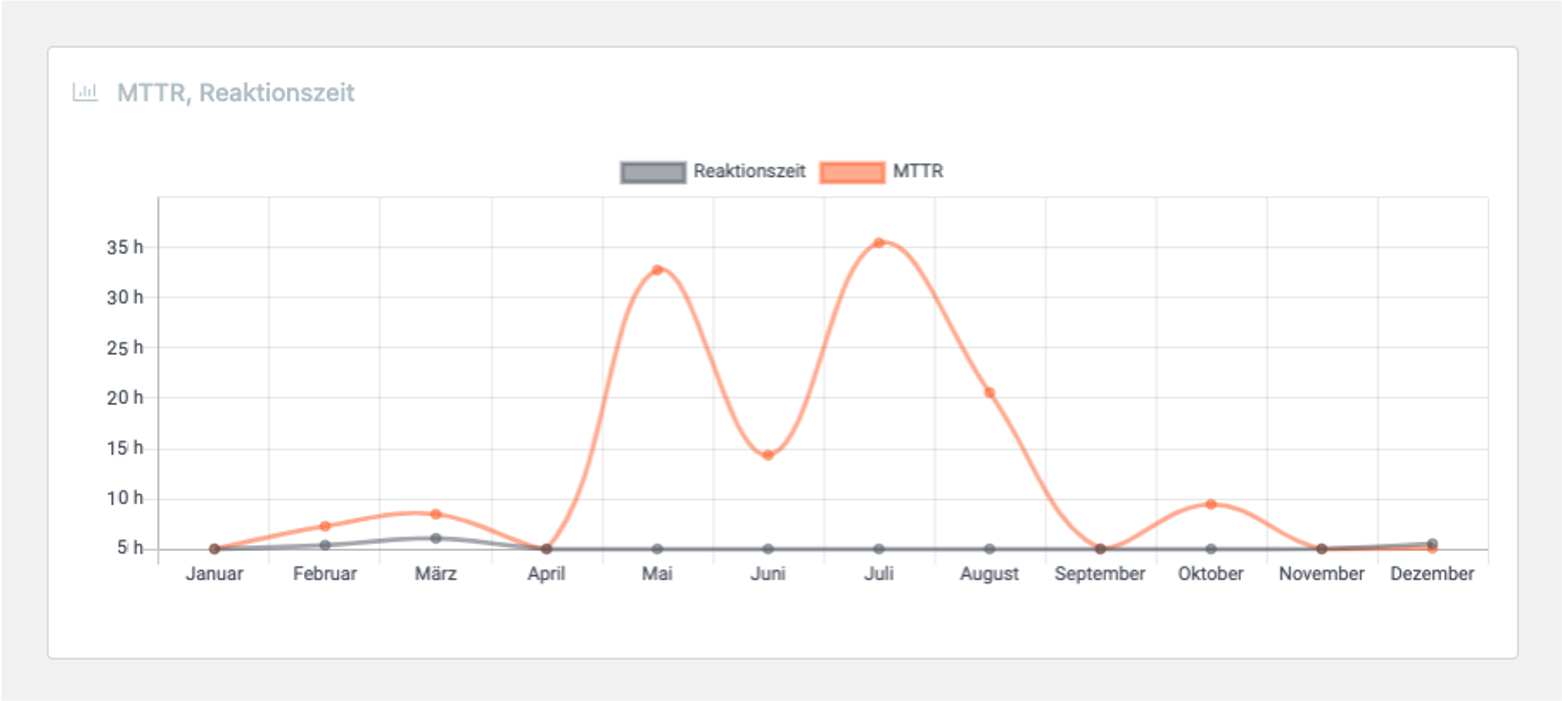

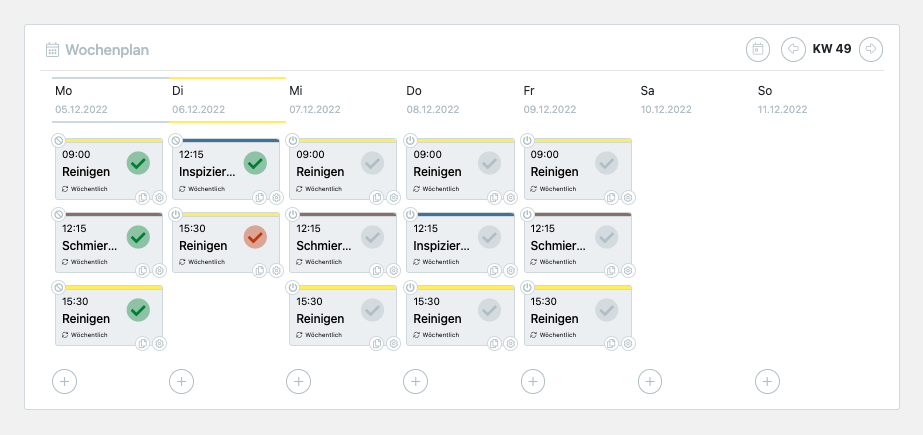

Reactive and preventive maintenance

Spare part management

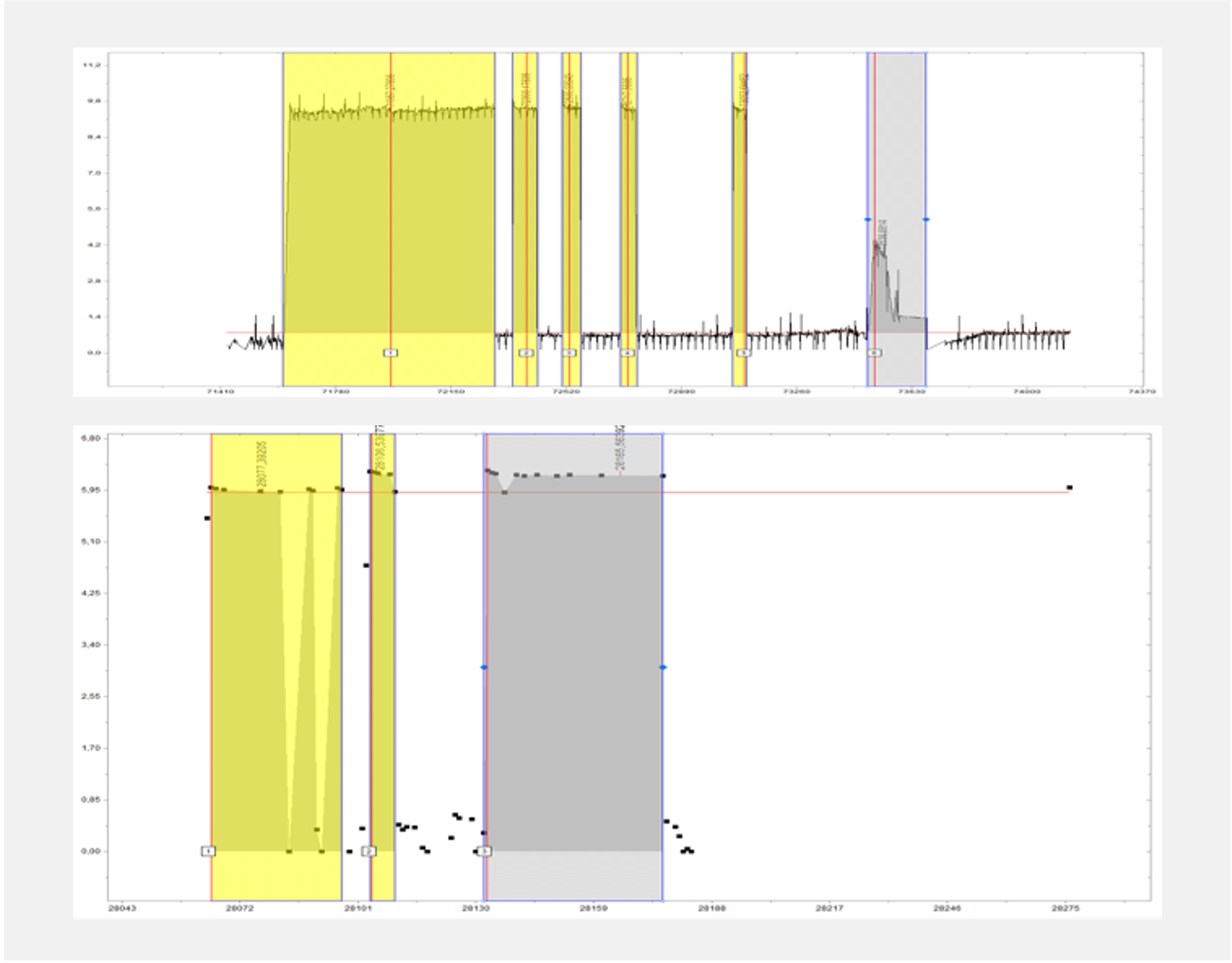

Condition monitoring

Book a demo Learn more

We are trusted by international market leaders: